Fleet & Maintenance Management

Mission-Ready Assets. Zero Guesswork. Full Control.

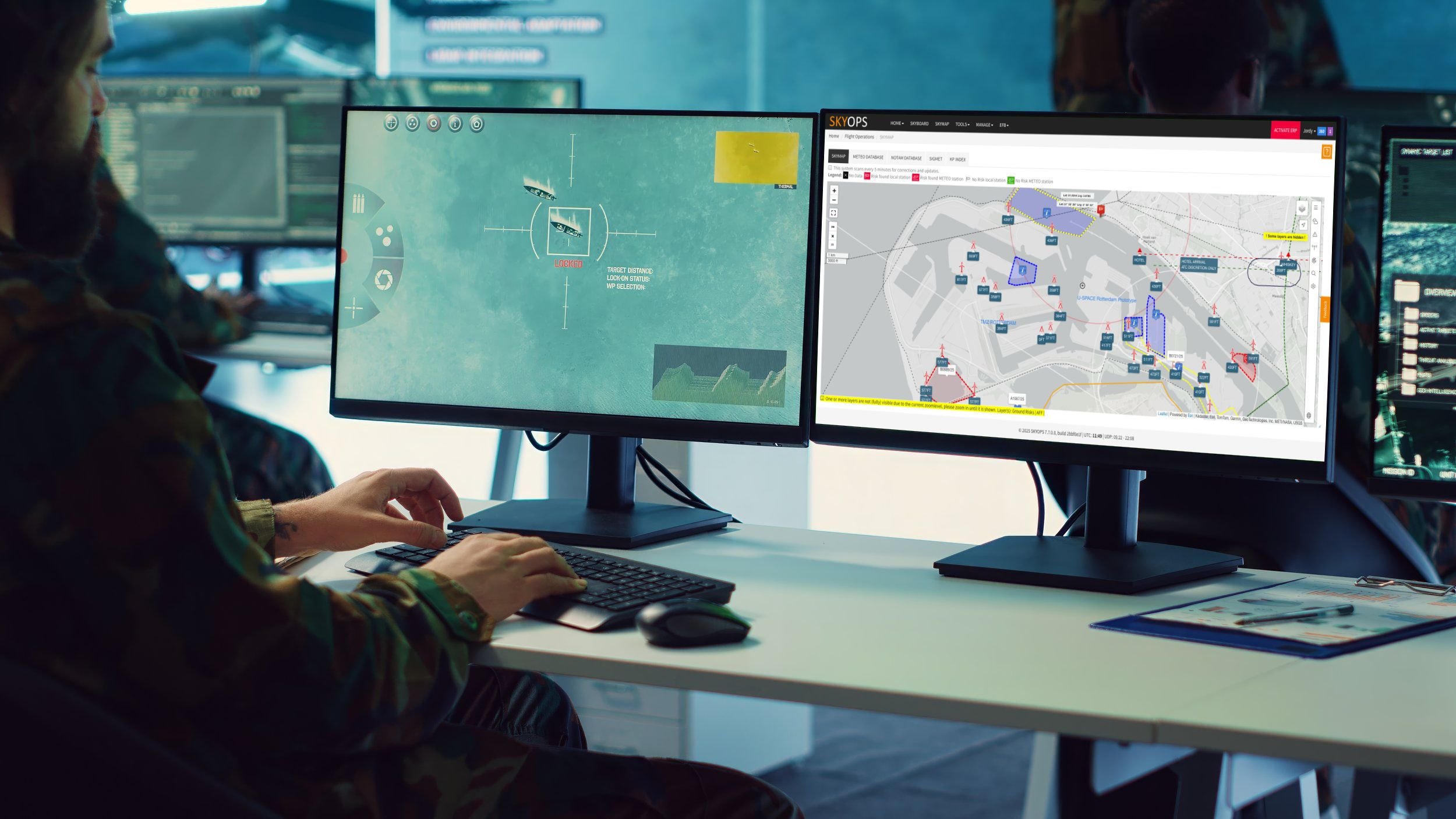

In tactical aviation, knowing your fleet is available isn’t enough. You need to know it’s operational, compliant, and properly assigned, before the mission even begins. SKYOPS brings structure, predictability, and intelligence to UAS, helicopter, and fixed-wing operations through real-time fleet oversight and integrated maintenance workflows. Every system, payload, and battery is tracked, qualified, and mission-linked, so command decisions are always based on fact, not assumption.

One System. Full Visibility.

Most fleet operations rely on disconnected spreadsheets, delayed updates, or paper logs. SKYOPS centralizes the entire asset structure (airframes, payloads, batteries, subcomponents) into a single operational layer. Telemetry feeds real-time usage and status data directly into asset records, so you always know what’s available, where it’s located, and when it’s next due for inspection. Maintenance teams work in sync with schedulers and flight crews, removing friction and manual handovers.

The Platform Manages:

1

Real-time system status dashboards for all assets.

2

Location and usage tracking across departments and shifts

3

Inspection scheduling and service history at component level.

Integrated Maintenance, Not Just Reminders

SKYOPS tracks operational hours, part cycles, and inspection intervals automatically, based on actual mission use via telemetry. Debriefed flights update wear and usage statistics instantly, keeping aircraft airworthy without over-servicing. Unscheduled defects are captured directly in the debrief process and trigger alerts for maintenance staff. Documentation, logs, and regulatory flags are recorded and fully auditable.

Maintenance Management Tools Include:

1

Automatic hour or cycle updates via mission debriefs.

2

Defect and remark reporting linked to system and mission ID.

3

Workbench and inspection queue tracking for parts and airframes.

No Mission Without Compliance

Whether you operate in a regulated airspace or under internal safety standards, every asset must meet technical and documentation requirements. SKYOPS blocks the use of systems or payloads that are non-compliant, due for inspection, or involved in unresolved occurrences. Maintenance status, inspection logs, and part lifecycle data are available instantly to planners and dispatchers, so the wrong aircraft never gets assigned.

Supporting Tools Include:

1

Operational lockouts for overdue or defective equipment.

2

Documented inspection trails with digital signatures.

3

Lifecycle tracking for each part, payload, and airframe.

Tactical Readiness by Design

SKYOPS ensures your fleet isn’t just ready - it’s proven ready. Every mission draws from a real-time readiness status, ensuring pilots only see airframes that meet operational criteria. If a battery is near end-of-life, it’s flagged. If a payload was removed in maintenance, it’s reflected in the dashboard. The system prevents oversight before it can happen.

Why It Matters

When fleet management is disconnected from operations, risk increases and availability suffers. SKYOPS brings both into a shared environment where usage, service, compliance, and dispatch are always aligned. No assumptions. No manual gaps. Just fully synchronized mission readiness from cockpit to workshop.